Expertise That Drives Performance

We support the construction, commissioning, and running of your critical LNG assets with market-leading procedures, methodologies, personnel, and equipment packages. From pre-commissioning to gasification, re-gasification, operations, and maintenance, we’ll ensure your project is delivered on time and within budget.

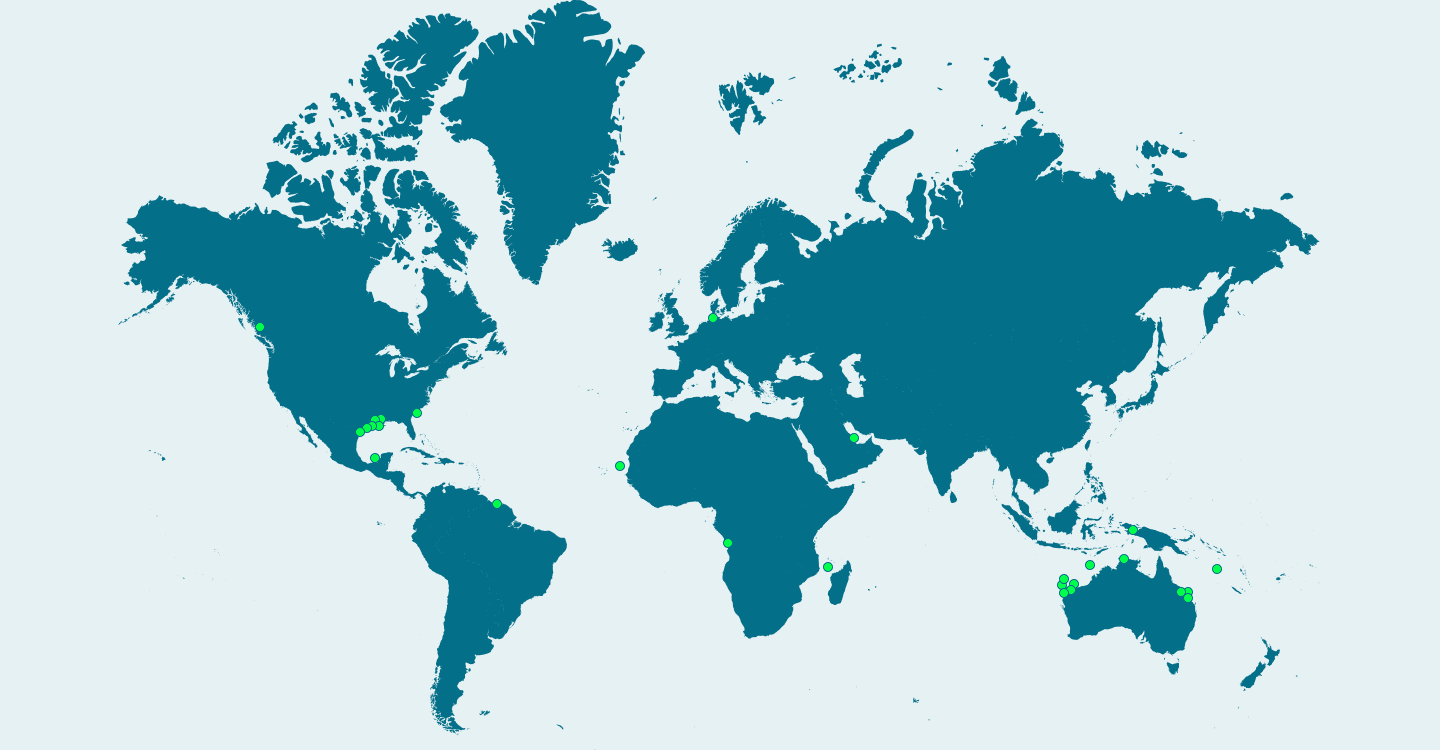

Our strategically located teams have successfully delivered bundled solutions for mechanical pre-commissioning packages on major LNG projects worldwide. That’s why you can trust us to support you through multiple phases, from construction completion to first cargo, operations, and maintenance.

Here are some of the projects we’ve played a vital part in delivering.

Global

EnerMech is a familiar presence in shipyards around the world. For the FPSO now moored offshore Mauritania, we were with the vessel every step of the way. We carried out project management, engineering, flange management, N2He leak testing, and tank purging in the shipyard in Qidong, China.

We also provided piping system integrity services in the shipyards in Singapore and Tenerife and handled N2He leak testing in the field in Mauritania. By bringing together our cross-regional resources, we’ve been able to bring schedule, consistency, and commercial benefits for our customer.

Case study

With You Every Step Of The Way

Angola

In Angola, we provide equipment, TAR support, and a multi-discipline workforce to address the diverse maintenance needs of the Angola LNG plant. This includes maintaining heavy vehicles, fabrication support, mechanical, electrical and instrumentation services, sewage treatment, planning, HVAC maintenance, catalyst handling, piping, and tower internal and heat exchange cleaning.

Case study

Meeting the Complex Needs of Angola LNG

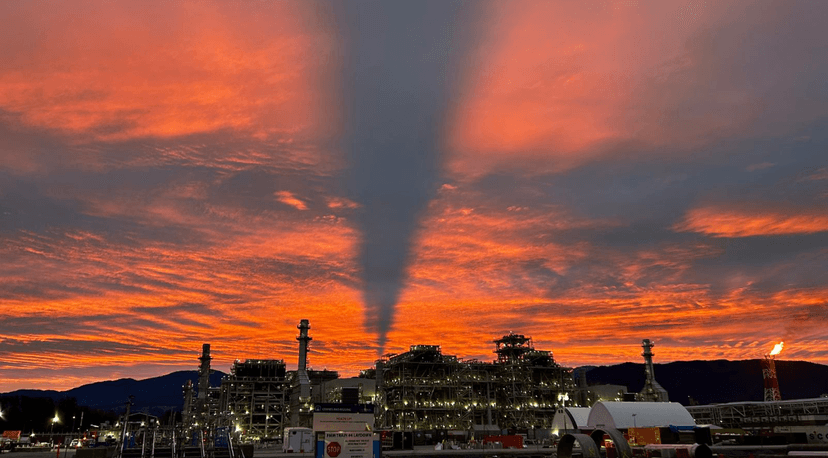

Canada

In Canada, we are executing the mechanical pre-commissioning and commissioning packages on the country's largest LNG project.

Our scope is to provide temporary nitrogen generation and water treatment utilities, including piping systems testing, valve seat leak testing, PRV calibration, lube oil flushing, degreasing, hydro milling, as well as cooling water cleaning and passivation and operational pressure leak testing.

Case study

Delivering LNG Success in Canada

Australia

Using our mulit-skilled teams and specialist equipment, we provided bundled solutions on Chevron Gorgon, Chevron Wheatstone, and INPEX Ichthys projects in Australia. These included nitrogen leak testing, lube oil flushing, chemical cleaning, and pipeline services.

Case study

Ichthys Onshore LNGCase study

Gorgon Onshore LNG

Germany

We fast-tracked the transformation of an existing oil terminal at Brunsbüttel port into the Elbehafen LNG regasification facility, enabling the country’s first direct access to the LNG market. Our scope included Commissioning Management System development, scoping, systemization, and full pre-commissioning, commissioning, and start-up services. By integrating commissioning experts early and enabling simultaneous multi-system execution, we ensured safe, efficient delivery - earning client praise for our agility and technical expertise.

Case study

Elbehafen Fast-Track LNG Delivery

Talk to an Expert

Connect with an EnerMech expert to access our innovative engineered solutions tailored for your complex challenges.