Overview

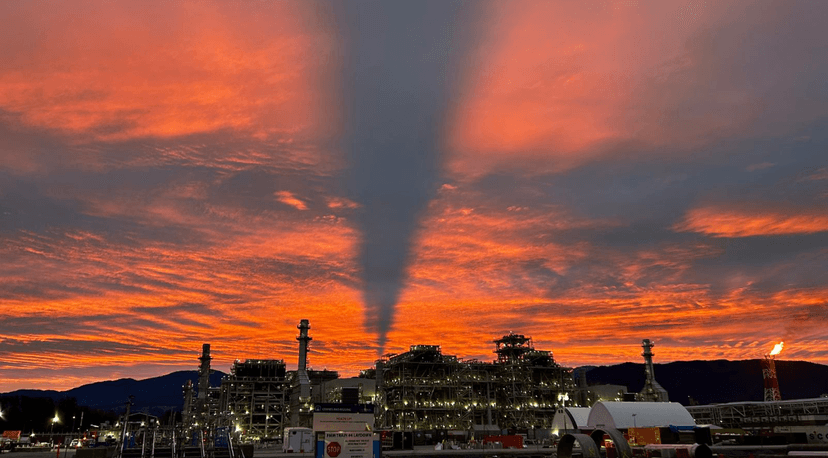

EnerMech supported the Angola LNG plant—one of Angola’s largest oil and gas investments—by delivering a fully integrated maintenance and Turnaround (TAR) solution. The project demanded coordination across multiple international locations, specialized equipment, and complex logistics. Leveraging its established presence in Angola, EnerMech deployed a multi-skilled workforce and equipment to ensure seamless execution, minimize downtime, and enhance operational reliability.

Key Highlights

250+ personnel mobilized for Turnaround (TAR) support, scaling from a core team of 60 for general maintenance.

Integrated service delivery through a single interface, reducing schedule risk and resource complexity.

Specialized capabilities including catalyst handling and tower internal cleaning.

Local logistics hub at SONILS base in Luanda enabled efficient personnel and equipment coordination.

Comprehensive maintenance coverage across mechanical, electrical, HVAC, instrumentation, and sewage systems.