Controlling Flow, Securing Reliability

Whether you need a single solution or an integrated package, our global valve services provide a comprehensive approach for any offshore system. We ensure traceability, conformity, and quality while minimizing the risk of downtime or critical system failure.

At EnerMech, we recognize the critical role valves play in your production and subsea systems. These components require expert management, testing, inspection, and maintenance during installation and throughout their operational life.

We deliver end-to-end valve solutions – procurement, specification, maintenance, repair, testing and technical support – across all valve types, including choke, relief, ball, gate, plug, butterfly, diaphragm, spherical, cone, needle, globe and specialist valves. Our services are built to maximize performance and reliability throughout the life-cycle. Plus, with seamless integration into our System Integrity Management (SIM) platform, you gain real-time digital oversight of these critical components.

Total Valve Management

Valve maintenance, repair, overhaul and certification

PSV recertification, repair and supply

Online Leak Sealing

Whether topside or subsea, we offer flexible, tailored solutions to meet your needs, all supported by advanced testing and expert technical support.

Specialist Valve Design and Manufacture

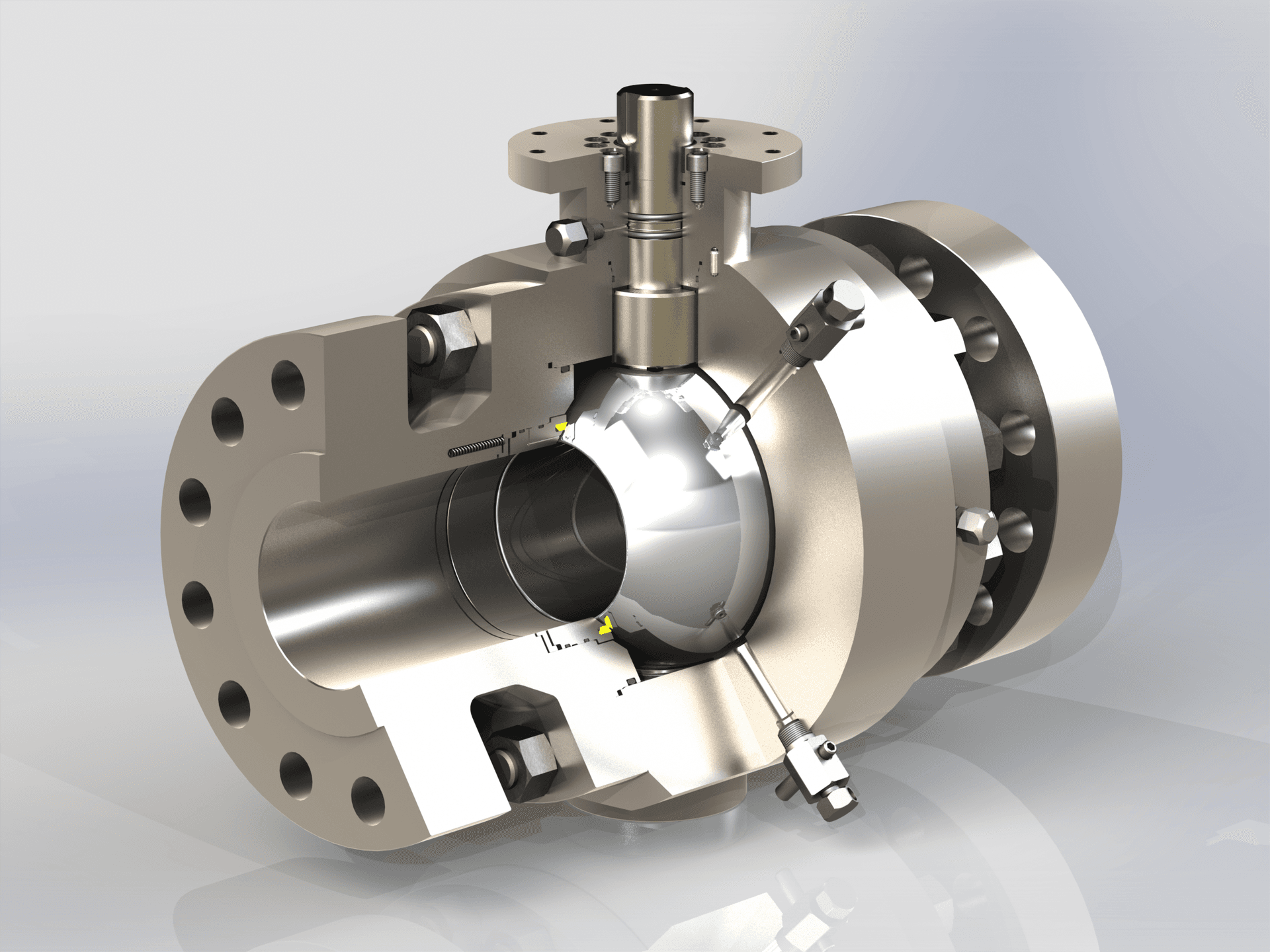

Our specialist valve design and manufacturing capabilities are built to meet the toughest demands of the energy sector. From concept to commissioning, we deliver high-integrity, severe-service ball valves that perform under pressure—every time.

Our flagship LG Ball Valve is a trunnion-mounted powerhouse, designed with advanced features that ensure reliability, safety, and longevity. Manufactured in-house using high-specification materials from our approved global supply chain, each valve is rigorously tested to international standards. The result? Exceptional structural integrity and reliable performance, wherever you operate.

Engineered to Perform

Every detail of our valve design is engineered for performance. From anti-blowout stems to low-torque profiles and ISO-compatible actuation, we build in reliability from the inside out. Our standard production range covers the specs that matter – size, pressure, temperature, and materials – so you get the right valve, right when you need it.

Design Features

Standard Production Range

We control every step – engineering, machining, assembly, and testing – so you get dependable lead times and a product that delivers on quality, every time.

Ross Wilson

Global Valves Delivery Manager

Talk to an Expert

Connect with an EnerMech expert to access our innovative engineered solutions tailored for your complex challenges.

Quicklinks

More Energy Solutions