Delivering Confidence Below the Surface

Across the asset life-cycle, EnerMech delivers comprehensive pre-commissioning, commissioning, and start-up services, along with maintenance, operations, and late-life support for subsea pipelines, umbilicals, and control systems.

Pipelines and Subsea

As subsea systems reaching greater depths and new projects emerging globally, EnerMech has emerged as a go-to partner for major deepwater and pipeline projects in key energy hubs. A market leader in pipelines and subsea pre-commissioning, we combine innovative technologies with the expertise of our multi-skilled teams to deliver integrated services across the asset life-cycle.

Harnessing our deep industry expertise, from construction through to late-life support, our skilled pipeline and umbilical teams deliver efficient, innovative, turnkey solutions.

Pre-commissioning, Commissioning and Start-Up

Maintenance & Operations

Late Life Support

Subsea Umbilicals and Control Systems

EnerMech delivers expert pre-commissioning and commissioning services for subsea umbilicals and control systems. Our multi-skilled teams carry out fluid, electrical, and fibre optic testing to safeguard system integrity at every stage—before, during, and after installation.

These complex systems demand precision and consistency. From FAT and SIT through to installation, commissioning, and long-term maintenance, we’re your trusted partner across the full life-cycle.

Hydraulic and Chemical

Electrical and Fiber Optic

Our teams build strong relationships and develop deep knowledge of your assets, ensuring tailored, effective solutions that drive success globally.

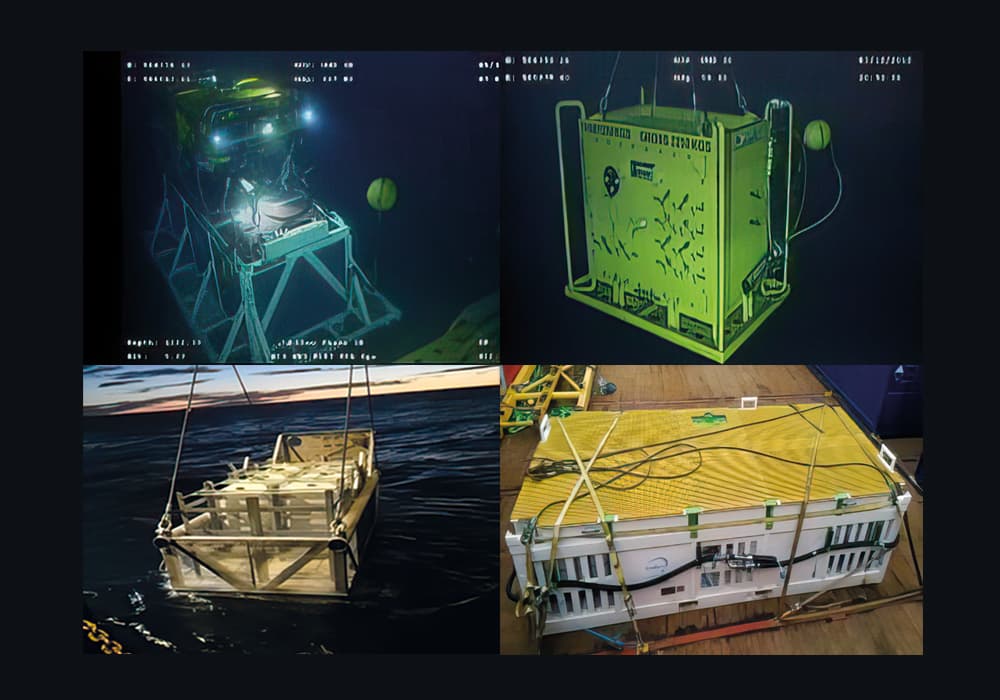

Subsea Technology

Over the past decade, we’ve pioneered a suite of subsea equipment tailored for operations in water depths ranging from 20m to 3,000m. Our technologies have been deployed over 150 times across more than 30 global projects –delivering measurable impact, efficiency, and savings. Whether used individually or as an integrated system, our solutions reduce vessel time, minimize crew requirements, and enhance operational flexibility.

From remote flooding and testing to chemical storage and real-time data transfer, we engineer for performance. EnerMech’s subsea technologies are proven, adaptable, and ready to support your full project scope – or work seamlessly alongside your existing contractors.