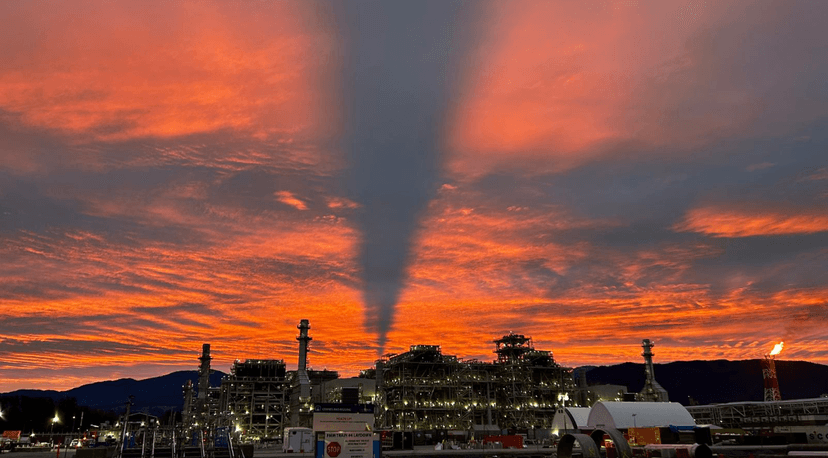

Energizing Energy

For over 50 years, EnerMech has been the trusted partner behind the world’s most complex energy projects — delivering the expertise, equipment, and technology that keep operations moving seamlessly.

Your Partner in Progress

We understand that in energy, everything is connected, and every solution has an impact. That’s why we focus on getting it right first time. Our commitment to safety, efficiency, and execution excellence keeps you moving forward with confidence, knowing you have a partner you can rely on.

Delivering Across the Asset Life-Cycle

What if one supplier could do it all? We can…

EnerMech specializes in delivering custom technical solutions across the asset life-cycle. Whatever service you need, we’ve got it covered – bringing unmatched value and support at every step.

Front-end engineering FEED

Engineering and construction

Pre-commissioning, commissioning, systems start-up and completions

Operations and maintenance

Shutdowns and turnarounds

Late life and decommissioning

Always Striving For Excellence

Ensuring your asset runs safely and efficiently is a top priority. With a standardized approach to service delivery across the globe, we provide ongoing support throughout your asset’s life-cycle, that maximizes uptime and minimizes operational risk.

Underpinned by our foundational principles of safety, quality, and integrity, we are always striving for operational excellence.

Charles 'Chuck' Davison Jr.

CEO

Global Capability, Local Delivery

Our multi-disciplined teams operate in the heart of major energy hubs, giving us the local insight and global reach to support our customers and consistently deliver our integrated solutions wherever they are.

Powered by People

Our people are the energy behind everything we do. Their dedication, creativity and passion powers us forward. That’s why we invest in their growth, offering continuous learning opportunities and clear career paths. In a culture of respect, we empower each other to lead, innovate and make a real impact every day.

Leaving a Lasting Positive Impact

For us, sustainability is about making a positive impact on our people, communities, and the planet – while upholding strong governance. We care for our people and the communities we’re part of, continually aiming to be a good employer, neighbor, and partner. Acting with integrity and ethics at our core, we make sure our actions reflect our values and drive lasting, sustainable success.